Products decription:

PLUSTRUSS system aluminum stage steel truss For Exhibitions and stadium

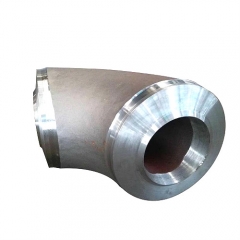

Pipe truss refers to a lattice structure formed by connecting round rods at the ends. The trusses make the truss structure economical in materials and light in weight. It is easy to form various shapes to adapt to different uses, such as simply supported trusses, arches, frames, towers, etc.

Structural features

Compared with the grid structure, the tubular truss structure saves the lower chord longitudinal members and the spherical joints of the grid frame, which can meet the requirements of various building forms, especially the construction of round arches and arbitrary curved shapes is more advantageous than the grid structure. Its stability in all directions is the same, saving material consumption. The steel pipe truss structure is developed on the basis of the grid structure. Compared with the grid structure, it has its unique advantages and practicability, and the amount of structural steel is also more economical.

Tube truss (14 sheets)

Compared with traditional steel trusses with open cross-sections (H-shaped steel and I-shaped steel), the material of the pipe truss structure is more evenly distributed around the neutral axis, so that the cross-section has good compressive and flexural-torsional bearing capacity and greater rigidity. Without gusset plate, the structure is simple. The most important thing is that the tubular truss structure is beautiful in appearance, which is convenient for modeling and has a certain decorative effect. The overall performance of the pipe truss structure is good, the torsional rigidity is large, and the appearance is beautiful. It is easy to manufacture, install, turn over, and lift; the steel pipe roof truss made of cold-formed thin-walled steel has light structure, good rigidity, steel saving, and can give full play to The advantages of material strength, etc., are more economical, especially in the strut and support system controlled by the slenderness ratio. Buildings with this structure are basically public buildings. The structure has the characteristics of beautiful appearance (it can be built into flat shape, round arch shape, arbitrary curve shape), convenient production and installation, good structural stability, strong roof rigidity, and good economic effect.

Application

A truss refers to a lattice structure composed of rods connected to each other at the ends. A tube truss means that the rods in the structure are all round tube rods. In most cases, the rods in the truss are only subjected to axial tension or pressure, and the stress is evenly distributed on the cross section, so it is easy to play the role of the material. These characteristics make the truss structure economical and low weight. It is easy to form a variety of shapes to adapt to different purposes, such as simply supported trusses, arches, frames, and towers. Therefore, truss structures are used in many large-span stadium buildings today, such as exhibition centers, stadiums, and other large It has been widely used in public buildings.

Most of the rods in the truss structure are connected by welding at the nodes. Before welding, the web rods and chords need to be cut according to the weld shape of each rod to be welded, which requires the web rods Intersecting line cutting and chord grooving are performed at the end. Since the bars in the truss structure intersect with the bars in the form of intersecting lines, the cross-sectional shape of the ends of the bars is relatively complicated, so in the actual cutting process, two methods of automatic mechanical cutting and manual cutting are generally used. Processing

FAQ

1. Q: What certificate do paris- fitting Truss have?

A: SGS and TUV certification.

2. Q: What is the terms of payment?

A: We accept Western Union, by T/T, 30% of invoice value as deposit, 70% balance paid before shipment, and some others.

3. Q: Where is the loading port?

A: Port Tianjin Cangzhou or Ports in Tianjin

4. Q: What is your packaging?

A: Air bubble film or carton or flight case.

5. Q: How long the deliver time?

A: General it is about 5-15 days.

6. Q: What is your after-sales service?

A: Free parts provided once broken within one year.

7. Q: Do paris-fitting Truss accept OEM order?

A: Yes, we welcome OEM order as well.

8. Q: Do paris fittingETruss accept customized logo order?

A: Yes, we can make logo on the truss for clients.

Our Service:

1. Well trained sales team service for you.

2. Small MOQ, usually sample is available.

3. Support OEM & ODM: we can print logo or customs package according to our client’s requirement.

4. Top quality: we have professional QC team to control the quality.

5. Timely delivery: we can send goods within 10~40 days after payment, it depend on products and quantity.

6. We work with DHL, UPS, FedEx, TNT and EMS for small order. For large order we can arrange shipment by air or by sea.

7 Satisfactory service: we treat clients as friends and 24 hours customer service.

Contact Details:

website:www.paris-fitting.com

Email:admin@paris-fitting.com /dingxueliang0818@aliyun.com

Whatsapp &We chat:0086-18330713028

Skype:naruto5448

Fackbook store::442237309934712